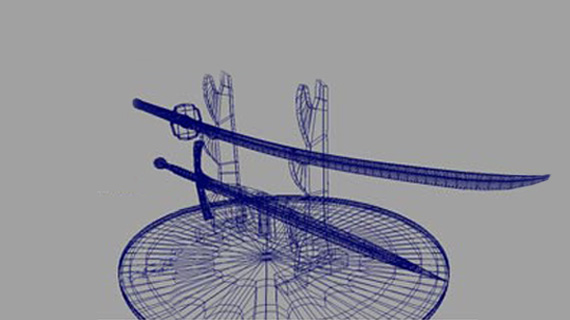

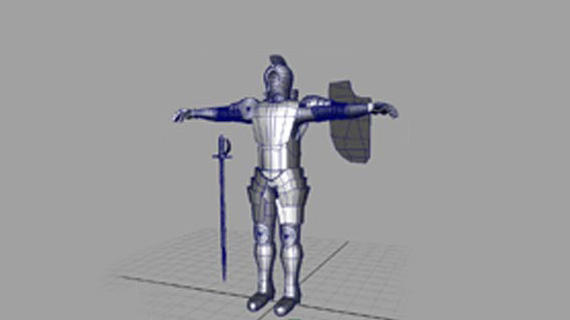

Weapons and Armor Designs

Designing weapons and armor has become our forte due to the strict quality standards of our manufacturing processes and an extremely accomplished and skillful workforce who hold more than 60 years of experience in this field.

Designing weapons and armor has become our forte due to the strict quality standards of our manufacturing processes and an extremely accomplished and skillful workforce who hold more than 60 years of experience in this field. Such expertise enables us to know the precise mixture of specifications and materials used in fashioning the best possible weapons and armor. (A significant chunk of our products are handmade.) It also allows us to provide you with products tailor-made according to your specifications and requirements. Further, the vast array of materials and techniques that we imbibe in our production process helps to achieve superior quality products and make us among the leading firms in this market. Also, our Research and Development team maintains the authenticity of our output, including its minuscule features and aspects.

Initially, we manufactured niche “handicraft type” items and did not outsource much work. Today, Windlass has developed processes and acquired equipment capable of undertaking virtually any type of work in-house. As a result,

Our manufacturing facility is not one factory, but a combination of several factories. Windlass has a complete leather shop, wood working shop, metal working shop, tool room to build dies and specialty jigs, casting, painting, and plating. The proprietary processes have brought quality and consistency to the handicraft trade.